Post Preview

Having a budget to stick to when printing a magazine is essential. Otherwise, you could spend less. Joe Makes has created a video to help you save Money on your next print run without compromising quality.

Using a house stock chosen for its reliable reproduction qualities will also reduce costs. For example, a textured stock such as Edition or Galerie Satin can add tactility to the cover without creating a high printing cost.

Choose the Right Size

There are a few key things to keep in mind when selecting a printing company for your magazine:

- Ensure that the company has the right equipment and specializes in your magazine type.

- Make sure that they use high-quality paper.

- Choose the right size.

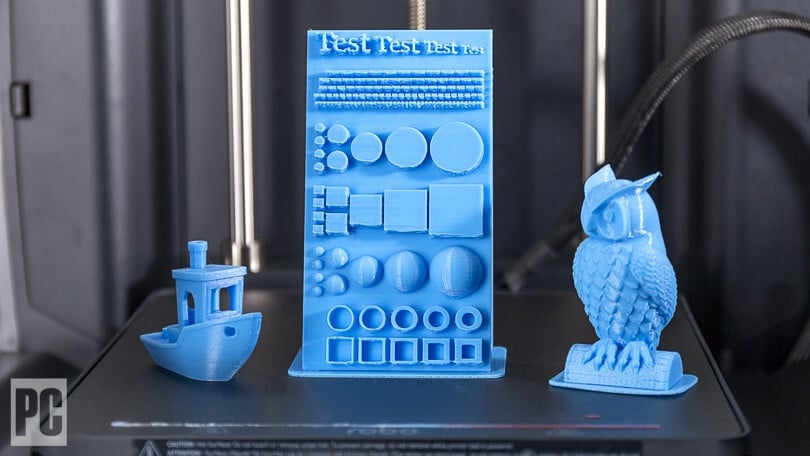

You want to choose a size that will fit your 3D printing magazine and not be too large or too small. You should also consider the number of pages and the ink colors. Most full-color magazines use CMYK (Cyan, Magenta, Yellow, Black) inks.

Most magazines are printed on gloss art paper, which makes them look vibrant and eye-catching. But be sure to consider the weight of the paper when ordering. For example, if your magazine is 64 pages plus four covers, you must call 80 sheets of paper.

Printing in smaller denominations leads to more plates being used and higher costs, so try to stick to section sizes multiples of 16. This will also save time as you will have fewer sheets to fold.

Go for CMYK Printing

Most magazines are printed in full color, meaning they’re printed using CMYK (cyan, magenta, yellow, and essential (black)). To ensure that the colors you see on your screen will print correctly on paper, it’s necessary to save your files in CMYK. This will help to prevent any unexpected color shifts or distorted images, which can ruin the overall look of your magazine.

Choosing a paper stock that looks premium without breaking the bank is essential when printing a magazine. Many publishers add texture to their magazines using textured stocks, but this can be expensive and difficult to reproduce accurately. Instead, consider using a white stock with a cream tint to give your magazine a similar effect at a fraction of the cost.

A good print house will understand your vision for the magazine and know how to achieve it within your budget. They will also be able to advise you on alternative options for achieving the desired effect, such as embossing or laminates, which are much cheaper than using a textured stock.

Avoid Bleeds

Printing a magazine is a complex process with many associated costs. It is essential to be aware of these costs to plan accordingly and avoid unexpected expenses. Moreover, choosing a printer with experience with printing magazines is necessary. This will ensure that your publication is printed in the best quality possible.

Understanding how to express your page count is essential to ensure everything is evident with the printer. The easiest way to do this is by describing it as the interior page count plus four. This will ensure that the cover is included in the total page count and make it easier for the printer to calculate your cost.

A common concern of indie publishers is the use of textured stock for the cover, as this adds a premium feel and can create a sense of luxury. However, this often proves to be expensive, especially for smaller productions. Instead, a simple aqueous coating on an untextured stock can have the same effect at a much lower price point.

Use Compatible Ink Cartridges

While plenty of cheaper printer ink alternatives exist, most don’t perform as well. For a few pounds more, you can buy compatible ink cartridges that will give you twice as many prints for the same price. These cartridges are a reservoir of hydrophobic foam and ink, which means you can refill them with any brand of ink.

It is also worth remembering that each magazine page counts four pages, including the cover. So, if your magazine is printed in black and white, you can save around PS700 by dividing it by 4.

One of the most environmentally friendly ways to print a magazine is using recycled paper stock. Recycled papers are made from wood pulp, cotton fiber, and other non-fibrous plant material. They are much less polluting than uncoated, coated, and sulphate-based paper stocks. Also, using recycled paper helps reduce the amount of slag, composed of iron ore and chromium mixed with limestone and coal, extracted from the earth in environmentally harmful ways.

Go for Offset Printing

With thousands of printing businesses, finding one that delivers a quality product can be challenging. But there are a few simple things you can do to ensure your print job is up to standard.

One thing you can do is opt for an offset printing service, which produces beautiful results on almost any kind of material. While it takes longer to set up than digital printing, it’s more cost-efficient once the initial setup is complete. It’s also more scalable so that you can produce large numbers of prints quickly and easily.

The type of paper you use is another factor that can affect your printing costs. For example, you might choose a heavier, more luxurious stock for the cover while using thinner paper for the inside pages. Then, you could choose a special coating to make your magazine stand out from the competition.

Choosing the right paper stock can help you save Money on printing without sacrificing quality. For instance, Limbo, a new magazine launched during the lockdown to support freelancers, chose a high-bulk stock like Essential Velvet 110gsm, which reduced shipping costs by 15% and has the same opacity as more expensive 130gsm silk stocks.